Select the Right Gelato Freezer for your Dessert Business

October 2, 2025 By: admin

In the case of an ice-cream or gelato freezer (or even when you give thought to opening one), how your product will be packaged and preserved can be both life and death to your business. A refrigerated display case is one of the most essential equipment. This paper will guide you through the major considerations during the selection of display refrigeration of frozen desserts like controlling of temperature, energy consumption, design, functionality and maintenance.

Why the Display Matters

Frozen dessert is not simply about taste but presentation, texture and freshness are also vital. An artfully crafted refrigerated display will also guarantee that your product remains at the ideal temperature, and does not freeze burn, and finally, looks appealing to the eyes of your customers. When your display breaks down (e.g. temperature changes, fogging, ice formation), your product quality is compromised, and that decreases sales and customer confidence.

Stability and temperature Control

Accurate and stable temperature control is one of the most serious requirements. Frozen foods such as gelato freezer have a smaller temperature range than generic frozen food do.Excessive temperatures cause the product to melt or become soft, whereas low temperatures cause the product to harden and lose creaminess.

- Find units that have a close control of temperature (usually within the range +-0.5 degC or less).

- Select a well insulated low thermal leakage system.

- A forced air circulation or dynamic cooling is implemented so as to ensure there is a uniformity in all trays.

- It must have a good defrosting system, one that is automatic or programmable will minimize the amount of ice that forms and still preserve the integrity of the product.

Humidity and Cold Air Control

Humidity control is also critical, in addition to temperature. Dry air may lead to crusting or the creation of ice crystals in the surface of your dessert, which damages the texture. In some systems, a humidity control or an air discharge is controlled to minimize the risks of dehydration.

The direction of cold air flow also counts: air vents are to be constructed in such a way that they do not blast the product surfaces directly and thus dry them up. Equal airflow ensures that there is uniform quality throughout the display.

Energy Saving & operation expenses

Profitability can be determined by the cost of electricity. The modern designs of refrigerators are to minimize the amount of energy used without loss of performance.

- Variable speed fans and high-efficiency compressors can be adjusted automatically according to the demand.

- Insulation (foamed in place, vacuum panels, etc.) is good to reduce heat gain.

- Thermally broken frames, low-E; glass doors (doubled or tripled); and low-E coating can be used to minimize the amount of heat ingress through the ambient conditions.

- Night modes or economy modes are able to minimize power consumption at closing hours.

In the case of a potential purchase, approximate the operating lifetime cost of that product instead of the cost of the purchase. The energy savings can be over 5-10 years, which can be better than the differences on upfront cost.

Display Design & Visibility

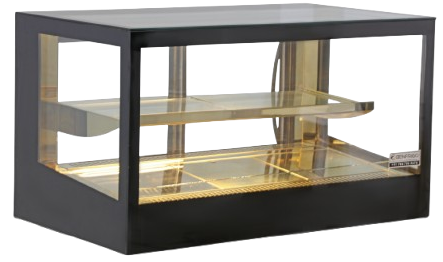

It is also your display unit which is your showpiece, the customers will first visit this and visual appeal will make purchasing.

- Use panoramic, curved or tilted glazing to ensure optimum visibility and reduce glare.

- Use anti-fog and low-reflection glass, which has a high transmission rate to maximize viewing even on a bright day.

- Internal LED lights must be used to evenly light without warming the product.

- Multi level trays / risers assist in the depiction of the variety and the depth.

- The service side (sliding doors, hinged lids) should be easy to access, which is why it is crucial to be fast and hygienic.

An intellectually designed display stimulates impulse buying and perceived values to your desserts.

Capacity, Size, and Layout

Selecting the correct size depends on production volume, shop layout, and future growth plans.

- Estimate peak demand (e.g. weekends, holidays), and size the capacity to handle it.

- Leave margin for growth — upgrading later may be more expensive.

- Think of tray size: standard insert pans versus custom molds; spacing matters for airflow.

- Ensure the refrigeration unit footprint fits your shop layout, allowing staff movement and customer flow.

- Consider modular or multi-unit setups — you may start with a single module and expand later.

Access, Serviceability & Cleaning

Frequent cleaning, maintenance, and service access are a reality in the foodservice world. A design that simplifies these tasks will save you time and money in the long run.

- Removable trays, slide-out access, and hinged panels ease cleaning.

- Easily reachable compressors, condensers, and coils facilitate maintenance.

- Service diagnostics, alarms, and self-check functions add peace of mind.

- Materials should be corrosion-resistant and food-safe (stainless steel, powder-coated surfaces, sealed joints).

A display that’s hard to clean or service will degrade faster and incur higher operational costs.

Compliance & Food Safety

Frozen dessert equipment must comply with health and safety regulations.

- The design must prevent contamination (no exposed refrigerant, sealed caps, hygienic surfaces).

- Satisfy local food safety laws — temperature logs, alarms, HACCP integration.

- Access doors must seal properly to prevent external contamination.

- Certifications (UL, CE, NSF, etc.) may be required depending on your region.

Refrigerant & Environmental Impact

Refrigerants matter both for performance and environmental compliance.

- Prefer units using lower-GWP (global warming potential) refrigerants like R290 or R600a, which are more eco-friendly.

- Ensure your unit meets environmental regulations and emissions standards.

- Proper design minimizes refrigerant charge and leak risks.

- Energy-efficient designs also reduce carbon footprint indirectly.

Cost vs. Value Consideration

When comparing options, many shop owners focus only on the upfront cost. Don’t fall into that trap.

- Assess the total cost of ownership (purchase price + power + maintenance + lifespan).

- A slightly more expensive, efficient unit may pay for itself within a few years.

- Factor in downtime, repair costs, and resale value.

- Consider warranties, parts availability, and local service support.

Tips Before Buying

- Request temperature performance curves, ice-load tests, and cooling recovery times from the vendor.

- Visit existing installations or reference sites to see the unit in operation.

- Check warranty terms, spare parts availability, and service network.

- Ask about modularity, expansion, and upgrade paths.

- Negotiate for energy-efficient options and future retrofits.

- Plan for ventilation, ambient load, and installation costs.

- Train your staff in proper hygienic cleaning procedures, and schedule preventive maintenance.

Final Thoughts

Choosing the appropriate display refrigeration is a strategic choice to any frozen dessert company. It is not just about the aesthetics, stability, energy performance, hygiene, servicing and longevity. An intelligent display design investment yields higher product quality, cost savings and increased customer loyalty.

Leave a Comment

Your email address will not be published. Required fields are marked *